Pinch valves are essential flow control devices used across numerous industries, from mining and wastewater treatment to food processing and pharmaceuticals. Selecting the correct pinch valve size is critical for optimal system performance, energy efficiency, and longevity. This comprehensive guide explores everything you need to know about pinch valve sizing, from understanding standard dimensions to calculating the right size for your specific application.

Understanding Pinch Valve Size Fundamentals

Pinch valve size refers primarily to the nominal diameter of the valve's sleeve or tube, which determines the flow path through the device. Unlike traditional valves with metal bodies and seats, pinch valves operate by compressing a flexible elastomer sleeve to control or stop flow. The size designation typically corresponds to the inner diameter of the sleeve when fully open, though manufacturers may use different measurement standards.

Standard pinch valve sizes range from as small as 6mm (1/4 inch) for laboratory applications up to 600mm (24 inches) or larger for industrial bulk material handling. The most common sizes fall between 25mm (1 inch) and 300mm (12 inches), which cover the majority of industrial fluid and slurry applications. When specifying valve size, engineers must consider not only the nominal diameter but also the connection type, pressure rating, and sleeve material compatibility.

The relationship between valve size and flow capacity is not always linear due to the unique operating mechanism of pinch valves. As the sleeve is compressed, the effective flow area changes, creating a variable restriction. This means that a pinch valve's flow coefficient (Cv) varies depending on the degree of pinch, making accurate sizing more complex than with conventional valves.

Standard Pinch Valve Size Ranges and Specifications

Pinch valves are manufactured in both metric and imperial sizing systems, with specifications that vary by design type and manufacturer. Understanding these standard ranges helps engineers make informed selections for their applications.

| Valve Size (Imperial) | Valve Size (Metric) | Typical Flow Rate (GPM) | Common Applications |

| 1/2" - 1" | 15mm - 25mm | 5 - 40 | Laboratory, small process lines |

| 1-1/2" - 3" | 40mm - 80mm | 50 - 300 | Food processing, pharmaceuticals |

| 4" - 6" | 100mm - 150mm | 400 - 1200 | Wastewater, chemical processing |

| 8" - 12" | 200mm - 300mm | 1500 - 4500 | Mining slurries, bulk solids |

| 14" - 24" | 350mm - 600mm | 5000 - 15000+ | Large-scale mining, dredging |

Different pinch valve designs offer varying size capabilities. Open body pinch valves, where the sleeve is exposed, typically range from 1 inch to 14 inches. Enclosed body designs, which house the sleeve within a protective casing, are available from 1/2 inch to 24 inches or larger. Inline pinch valves with flanged or threaded connections generally follow standard pipe sizing conventions, making integration into existing systems straightforward.

Critical Sizing Factors for Pinch Valve Selection

Choosing the correct pinch valve size involves analyzing multiple interdependent factors beyond simple pipe diameter matching. A systematic approach ensures optimal performance and prevents costly oversizing or undersizing issues.

Flow Rate Requirements

The volumetric or mass flow rate is the primary sizing criterion. Engineers should determine both the normal operating flow and peak flow conditions. Pinch valves can handle variable flow rates effectively, but the sleeve must be sized to accommodate maximum expected flows without excessive velocity. For liquids, velocities should typically remain below 15 feet per second to minimize erosion and pressure drop, while slurry applications may require lower velocities around 8-10 feet per second depending on abrasiveness.

Pressure Drop Considerations

Unlike fully open gate or ball valves, pinch valves introduce some pressure drop even when fully open due to the flexible sleeve geometry. The pressure drop increases as valve size decreases relative to flow rate. Acceptable pressure drop limits vary by application but generally range from 5 to 15 psi for most industrial processes. Calculating pressure drop requires knowing the flow coefficient (Cv) for the specific valve size and opening position, which manufacturers provide in technical datasheets.

Media Characteristics

The properties of the fluid or slurry significantly impact size selection. Viscosity affects flow resistance through the pinched sleeve, with higher viscosity fluids requiring larger valve sizes to maintain acceptable flow rates. For slurries containing solids, particle size relative to valve bore becomes critical—the valve diameter should be at least 3-4 times the maximum particle size to prevent blockages. Slurry concentration also matters, as higher solids content increases effective viscosity and may necessitate upsizing.

Operating Pressure Ratings

Pinch valve size and pressure rating are inversely related—smaller valves generally handle higher pressures due to the physics of sleeve compression. A 2-inch pinch valve might be rated for 150 psi, while a 12-inch valve of the same construction may only handle 40-60 psi. The system's maximum operating pressure must fall within the valve's rated capacity at the selected size. For applications requiring both large diameter and high pressure, specialty designs or alternative valve technologies may be necessary.

Calculating the Right Pinch Valve Size

Proper valve sizing combines engineering calculations with practical considerations. The following methodology provides a structured approach to determining optimal pinch valve size for most applications.

Begin by gathering essential system data including flow rate (Q), fluid density (ρ), viscosity (μ), operating pressure differential (ΔP), and allowable pressure drop across the valve. For slurries, also document particle size distribution and percent solids by volume or weight.

The basic sizing equation for liquids uses the flow coefficient relationship: Q = Cv × √(ΔP/SG), where Q is flow rate in GPM, Cv is the valve flow coefficient, ΔP is pressure drop in psi, and SG is specific gravity. Rearranging to solve for required Cv: Cv = Q / √(ΔP/SG). Once the required Cv is calculated, select a valve size with a published Cv value equal to or greater than the calculated requirement.

For example, if an application requires 200 GPM flow of water (SG = 1.0) with a maximum allowable 10 psi pressure drop: Cv = 200 / √(10/1.0) = 200 / 3.16 = 63.3. Consulting manufacturer data, a 4-inch pinch valve typically has a Cv around 200-250 when fully open, which would be significantly oversized. A 3-inch valve with Cv around 80-100 would be appropriate, providing safety margin while avoiding unnecessary cost and space consumption.

Velocity verification is the next critical step. Calculate the fluid velocity using: V = Q / A, where V is velocity, Q is volumetric flow rate, and A is the cross-sectional area of the valve bore. For the previous example with 200 GPM through a 3-inch valve: A = π × (1.5 inches)² = 7.07 in², Q = 200 GPM = 0.446 ft³/s = 192.5 in³/s, V = 192.5 / 7.07 = 27.2 in/s = 2.27 ft/s. This velocity is well below typical limits, confirming the sizing is appropriate.

- Apply a safety factor of 1.15 to 1.25 to account for variations in operating conditions, sleeve wear over time, and uncertainties in fluid properties

- For throttling applications where the valve operates partially closed, select a size 25-50% larger than calculations suggest to maintain controllability

- When handling abrasive slurries, consider undersizing slightly to increase fluid velocity, which can help prevent settling and maintain suspension

- Verify that the selected size matches available piping and connection standards to avoid costly adapters or custom fabrication

Common Sizing Mistakes and How to Avoid Them

Even experienced engineers can make errors when sizing pinch valves due to unique characteristics that differ from conventional valves. Understanding common pitfalls helps ensure successful installations.

Oversizing Issues

The most frequent mistake is selecting valves that are too large, often by simply matching the nominal pipe size without considering actual flow requirements. Oversized pinch valves suffer from poor control characteristics at low flows, increased cost, larger footprint, and potential for material settling in slurry applications due to insufficient velocity. An oversized valve also requires more actuation force to close, potentially necessitating larger, more expensive actuators.

To avoid oversizing, always calculate based on actual maximum flow rates rather than pipe size. Consider that pinch valves can effectively handle flows in pipes one size larger due to their full-bore design when open. For instance, a 3-inch pinch valve may adequately serve a 4-inch pipeline if flow calculations support this selection.

Undersizing Problems

Conversely, undersizing creates excessive pressure drops, high velocities that accelerate sleeve wear, and insufficient flow capacity during peak demand periods. In slurry applications, undersized valves are prone to plugging, particularly with fibrous or irregular materials. The increased turbulence in undersized valves can also cause premature sleeve failure.

Prevention requires thorough analysis of peak flow scenarios, including upset conditions and future expansion plans. Include appropriate safety factors in calculations and verify that maximum velocity limits are not exceeded. For critical applications, consider specifying the next size up if calculations fall near the boundary between two standard sizes.

Ignoring Sleeve Material Impact

Different elastomer materials have varying stiffness and compression characteristics that affect flow performance. A natural rubber sleeve may provide different Cv values than a EPDM or nitrile sleeve of the same nominal size. Temperature effects compound this issue—sleeves become stiffer at low temperatures and softer at elevated temperatures, changing the effective flow area and pressure drop characteristics.

Always consult manufacturer-specific Cv data for the exact sleeve material and operating temperature range planned for your application. When temperature variations are significant, size based on the worst-case condition (typically lowest temperature where the sleeve is stiffest and flow resistance highest).

Size Selection Based on Valve Type

Different pinch valve configurations have distinct sizing considerations that influence the selection process. Understanding these differences ensures the chosen design meets both functional and practical requirements.

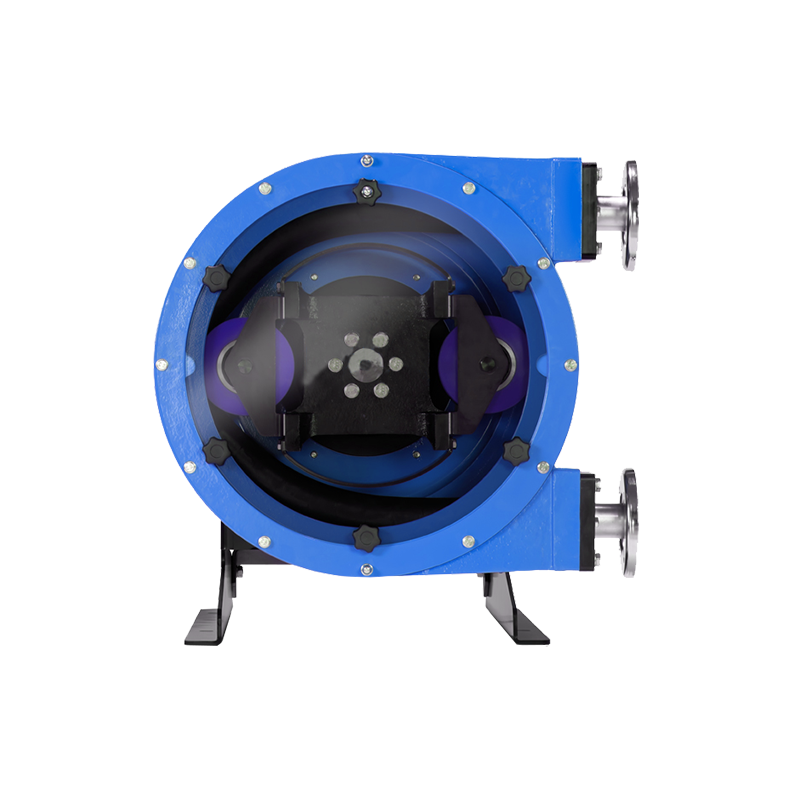

Open Body Pinch Valves

Open body designs feature an exposed sleeve that is replaced by simply releasing the actuator clamp. These valves are typically available in sizes from 1 to 14 inches and are popular for highly abrasive slurries where frequent sleeve replacement is anticipated. The open design allows for easy inspection and quick maintenance, making size selection more forgiving since sleeve changes can be performed in minutes without removing the valve body from the line.

When sizing open body pinch valves, consider the sleeve replacement frequency. Applications that wear sleeves rapidly may benefit from using a slightly smaller valve size that optimizes sleeve life through higher velocity (preventing settling) while accepting more frequent replacement of less expensive components.

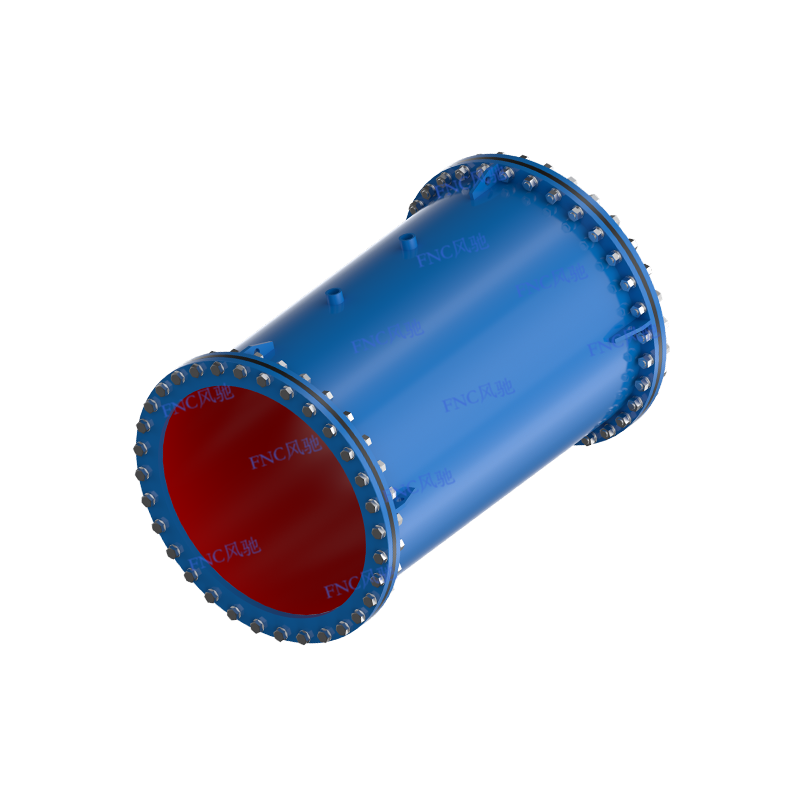

Enclosed Body Pinch Valves

Enclosed designs protect the sleeve within a rigid housing, offering better support for higher pressures and providing containment for hazardous materials. These valves range from 1/2 inch to 24+ inches and are ideal for clean fluids or mildly abrasive services where sleeve life is measured in years rather than months. The enclosed construction adds cost and complexity to sleeve replacement, making accurate initial sizing more critical.

Size selection for enclosed valves should prioritize long-term reliability and minimize the risk of undersizing, as correcting a sizing error requires complete valve replacement. The additional structural support allows enclosed designs to handle higher pressures at larger sizes compared to open body equivalents, which may influence size selection in high-pressure applications.

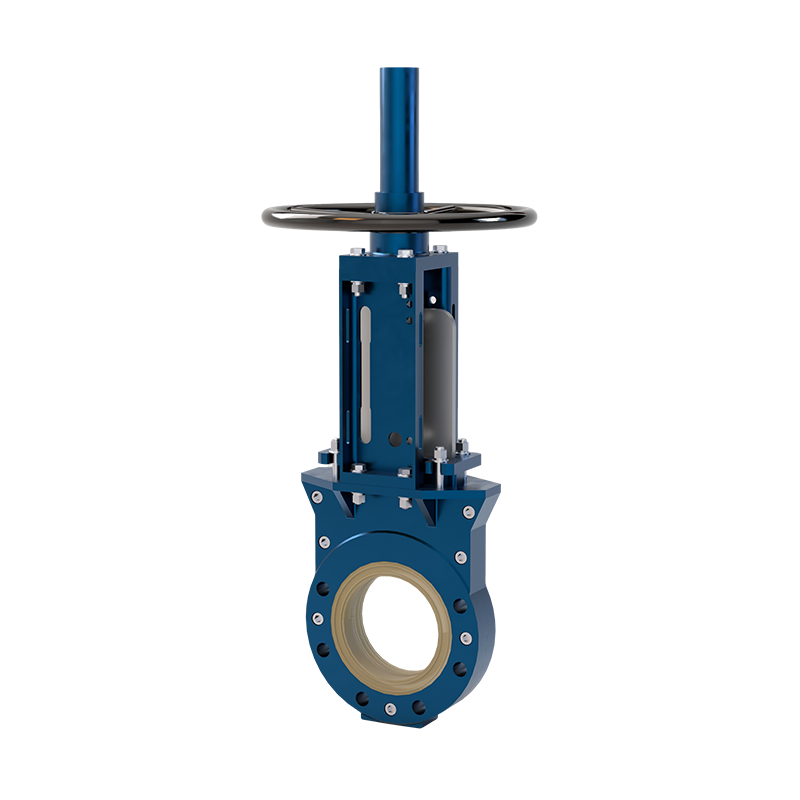

Air-Operated vs. Manual Pinch Valves

Actuation method affects practical size limits. Manual pinch valves are typically limited to 6 inches or smaller due to the physical force required to compress larger sleeves. Air-operated pinch valves can handle the full size range up to 24 inches or more, using pneumatic cylinders or air bags to generate sufficient compression force.

For manually operated valves above 3 inches, verify that operators can realistically actuate the valve through a full duty cycle. Applications requiring frequent operation or precise throttling should use pneumatic or electric actuation regardless of size. The actuator requirement may influence size selection—a 4-inch air-operated valve might be more practical than a 3-inch manual valve if operating conditions demand remote control or automation.

Industry-Specific Sizing Guidelines

Different industries have established best practices for pinch valve sizing based on decades of operational experience with specific materials and process conditions.

Mining and Mineral Processing

Mining applications typically handle highly abrasive slurries with large particle sizes and high solids concentrations. Standard practice is to maintain slurry velocities between 8-12 feet per second to prevent settling while minimizing erosive wear. Pinch valve sizes in mining commonly range from 4 to 12 inches, with 6 and 8-inch sizes being most prevalent for tailings lines and concentrate transfer.

For mine dewatering and process water, velocities can be higher (up to 15 ft/s) since erosion is less concerning. Sizing should account for the maximum particle size anticipated—valve diameter should exceed particle diameter by a factor of 4-5 for irregular shapes. Cyclone underflow applications require particular attention as these contain the coarsest, heaviest particles and may necessitate larger valves than predicted by flow calculations alone.

Wastewater Treatment

Municipal and industrial wastewater applications involve fibrous materials, rags, and variable solids content that challenge conventional valves. Pinch valves excel here, with typical sizes ranging from 2 to 12 inches. The full-bore design prevents clogging, but sizing must account for potential flow obstructions. A common approach is to size for 50% higher capacity than average flow to handle storm events and peak loading periods.

For sludge handling, lower velocities around 5-7 feet per second prevent shearing of floc structures while maintaining adequate transport. Thickened sludge with 4-8% solids typically requires 4 to 8-inch valves depending on flow rates. Wastewater applications often benefit from selecting valve sizes one step larger than calculations suggest to provide a safety margin against the highly variable material characteristics.

Food and Pharmaceutical Industries

Sanitary applications demand smooth, cleanable surfaces and often use smaller valve sizes from 1/2 to 4 inches. Sizing priorities include avoiding dead zones where product can accumulate and ensuring complete drainability. Pharmaceutical processes may specify low shear to preserve product integrity, requiring larger valves to reduce velocities below 5 feet per second for sensitive formulations.

Food processing applications handling particulates like fruit pieces, vegetable chunks, or meat products should follow the 3x particle size rule minimum. Viscous products like sauces, dairy, and syrups require upsize adjustments based on viscosity—products above 500 centipoise may need valves 25-50% larger than water-based calculations suggest. Sanitary pinch valves must also accommodate CIP (clean-in-place) flow requirements, which may exceed normal process flows.

Connection Type and Size Compatibility

Pinch valve size selection must consider how the valve connects to existing piping systems. Connection incompatibility can negate the benefits of otherwise correct valve sizing.

Flanged connections are the most common for pinch valves 2 inches and larger, following ANSI, DIN, or other regional flange standards. The valve flange rating (150#, 300#, etc.) must match or exceed the piping system rating. Flanged pinch valves offer the advantage of standard bolt patterns and ease of installation but add length to the valve assembly that must be accommodated in piping layouts.

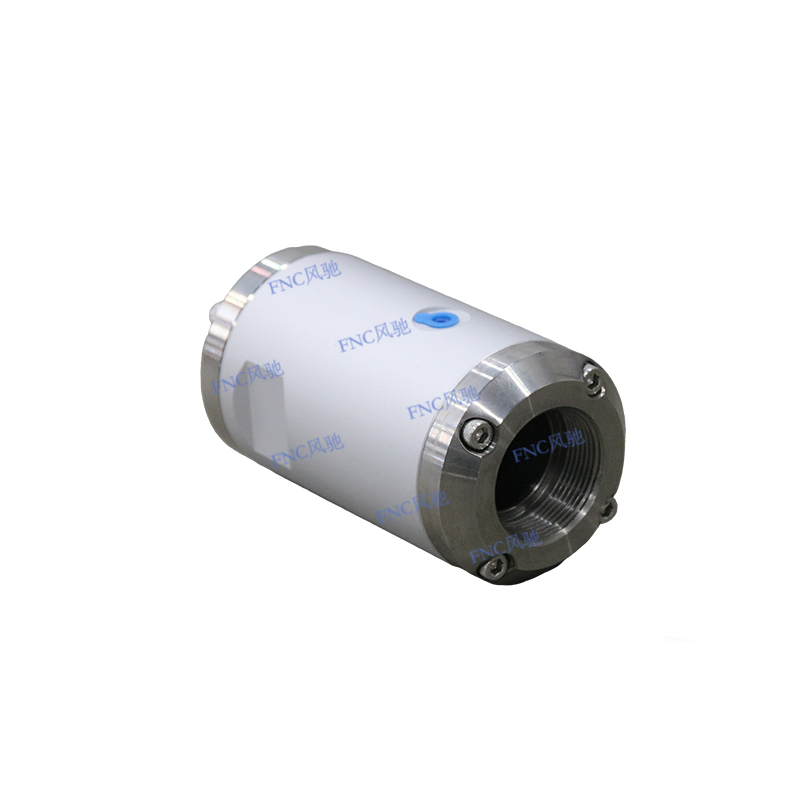

Threaded connections suit smaller valves (typically 2 inches and below) and provide compact installations. NPT, BSP, and metric threads are available depending on regional standards. Threaded pinch valves are popular in laboratory and pilot plant applications where flexibility and frequent reconfiguration are valued. However, threaded connections can be difficult to seal in high-pressure or vacuum services and are generally unsuitable for abrasive slurries that may cause thread wear.

Hose or tube connections use clamps to secure the valve sleeve directly to flexible hose, eliminating rigid pipe flanges entirely. This configuration is common in portable or temporary installations and smaller fixed systems. Hose connection pinch valves range from 1/2 to 4 inches typically, though larger sizes are available. Sizing must ensure the hose bore matches the valve sleeve diameter, and the sleeve extends sufficiently past the connection points to prevent edge wear.

- Wafer-style pinch valves fit between existing flanges without requiring separate valve flanges, offering the shortest face-to-face dimension but necessitating alignment precision during installation

- Reducer configurations allow connection of different pipe sizes on each end, useful when optimizing valve size independently of upstream and downstream piping

- Tri-clamp connections provide quick sanitary connections for food and pharmaceutical applications, available in standard sizes from 1/2 to 6 inches

Testing and Verification After Sizing

After completing sizing calculations and selecting a pinch valve size, validation through testing or detailed analysis confirms the choice will perform as intended. This step is particularly important for critical applications, large valves, or processes handling expensive or hazardous materials.

Flow testing with the actual process media provides the most reliable verification. If possible, obtain a sample valve in the proposed size and test it with representative fluid or slurry under expected operating conditions. Measure actual pressure drop, verify there is no plugging or settling, and confirm that actuation force requirements are acceptable. For slurries, run tests long enough to evaluate wear patterns and predict sleeve life.

When physical testing is impractical, computational fluid dynamics (CFD) analysis can model flow behavior through the pinch valve geometry. Modern CFD software can simulate the flexible sleeve, predict pressure distributions, identify potential dead zones, and calculate shear rates. This is particularly valuable for non-Newtonian fluids or complex slurries where empirical correlations may be unreliable.

Manufacturer consultation provides another verification pathway. Reputable pinch valve manufacturers have extensive application databases and can compare your requirements against similar successful installations. They may identify considerations unique to your application that standard sizing equations don't capture. Many manufacturers offer sizing software or application engineering support as complimentary services.

Document all sizing calculations, assumptions, and verification results for future reference. This documentation proves invaluable when troubleshooting issues, planning capacity expansions, or specifying replacement valves years after the initial installation. Include actual operating data once the system is commissioned to validate theoretical predictions and refine sizing approaches for future projects.

Future-Proofing Your Size Selection

Pinch valve sizing should account not only for current operating conditions but also for anticipated changes in process requirements, production capacity, and material characteristics over the system's expected life.

Production expansion plans should inform valve sizing decisions. If facility capacity is expected to increase by 30% within five years, selecting a valve size that accommodates this future flow may be more economical than replacing the valve later. However, balance this against the performance penalties of operating an oversized valve during the interim period. In some cases, installing appropriately sized valves initially and planning for eventual replacement proves more cost-effective than permanent oversizing.

Process flexibility requirements also influence sizing strategy. If the system may handle different products or materials in the future, size for the most demanding scenario. A valve sized for high-viscosity material will handle lower-viscosity fluids easily, but the reverse is not true. Similarly, if particle sizes may increase or solids concentrations could rise, size conservatively to maintain acceptable performance across the full range of possibilities.

Consider the evolving availability of replacement parts and sleeves. Selecting common, standard sizes ensures long-term parts availability and competitive pricing. Unusual or custom sizes may save initial costs but create supply chain vulnerabilities. Standard sizes like 2", 3", 4", 6", 8", and 12" have the broadest market support and most competitive aftermarket options.

Finally, evaluate the total cost of ownership rather than just initial valve cost. A larger, more expensive valve with longer sleeve life and lower maintenance requirements may cost less over its operational lifetime than a smaller, cheaper valve requiring frequent service. Size selection should optimize lifecycle economics, not just minimize capital expenditure.

EN

EN

English

English русский

русский Español

Español