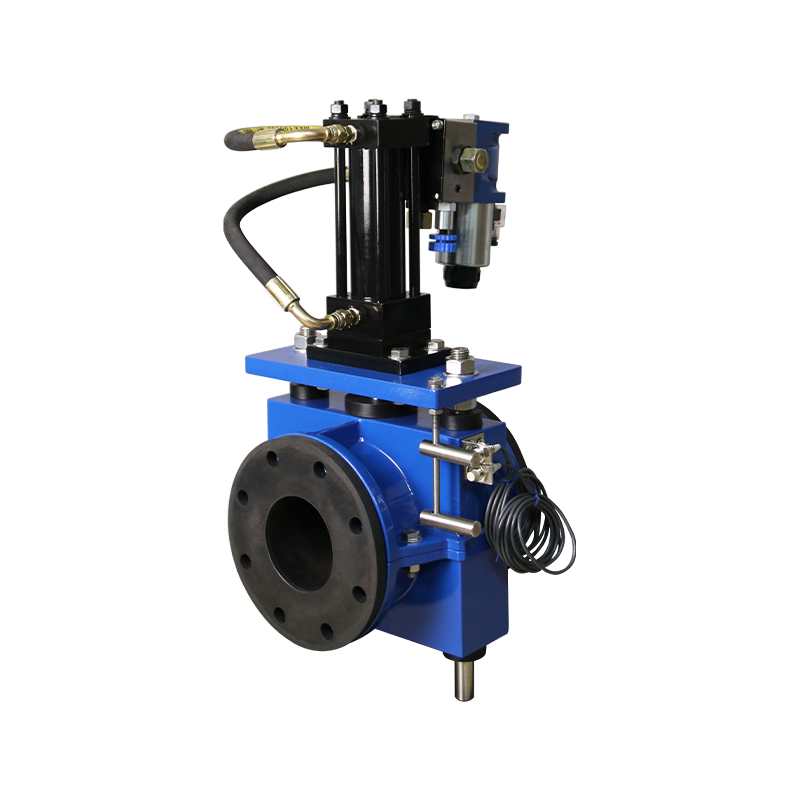

Performance Data

- Nominal Diameter: DN15 ~ DN2000

- Pressure Rating: PN6~PN40 (varies by size, connection type, and actuation method)

- Leakage Class: Class V

- Applicable Media:For standard rubber sleeves: mineral slurry, mud, paper pulp, etc. For other optional rubber sleeves: Corresponding lining materials are selected based on medium characteristics (such as temperature, pressure, particle size, corrosiveness, etc.).

- Temperature Range:For standard rubber sleeves: ≤ 80°C.For other optional rubber sleeves: Up to 160°C

- Flow Characteristic: Full-bore, unobstructed flow

Connection and Actuation Methods

- Connection Type: Flanged-type

- Actuation Method: Manual, Worm Gear, Pneumatic (Single Acting, Double Acting), Electric (On-Off Type, Modulating Type), Hydraulic, Pneumatic Modulating (with Positioner)

Applicable Scenarios: Mining, Sewage Treatment, Chemical Control Processes, Power Plants

Customization is available based on requirements.

EN

EN

English

English русский

русский Español

Español